Case Study – Use of Safety Tools Allmet Abrasives

Transocean Leader 2012

Area:

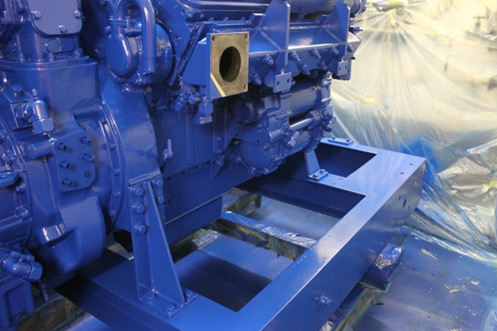

Cementing room. Diesel engines, piping, tanks, and structures/frames (skid).

Assignments:

Degreasing and high-pressure washing with high pressure and hot water, 500 bar pressure. Mechanical pretreatment of corroded parts. Spot painting of grinded and pretreated areas. Painting the entire unit (see photos below), changing colour from orange to blue.

Condition:

Some corroded parts, grease, oil, and other contaminants are on the surface. Cramped room with difficult access. Much wiring and instruments made blasting out of the question as surface preparation.

Alternative solutions:

A: Spot sandblasting/vacuum blasting with blasting equipment.

B: Mechanical pretreatment with Flap Disc/needle gun/knife.

C: Ultra High Pressure 2000 bar.

D: Mechanical pretreatment with Safety Tools Allmet ATEX-Tools.

Selected solution:

Alternative D. Use of Safety Tools Allmet grinding tools.

Justification for the chosen solution:

1: The tool does not emit hot sparks and therefore does not require permits for hot work.

2: Dust. Low RPM and no airborne dust with associated issues.

3: Clean: The rotary files provide a clean surface, ST 3 / Sa 2 ½.

4: Roughness: The machined surfaces gave a roughness of 50-75 microns. Which is well within the requirements according to NORSOK M 501

5: Productivity. The tool requires little rigging/screening before initiation. In addition, files have higher productivity than needle gun/flap discs.

Experiences with Safety Tool Allmet grinding tools

Job Design:

Simplified rigging, only compressed air hoses for connecting the tool. We did the job in less time than expected due to a higher capacity than standard tools for mechanical pretreatment. (Flap-disc, needle gun, and other standard options) abrasives equipment or grinding tools was not replaced, very little wear.

Economy:

Because a faster production method provides cost savings, the files are made of special steel and last long. The machines are very robust (tough) and long-lasting. When we finished this job, the grinding tool was still usable, and you can still use the tool on multiple jobs.

Quality:

The tool provides cleanliness and roughness following the requirements and in accordance with NORSOK M 501. Clean: St 3 / Sa 2 ½ ref ISO 8501-1.

Roughness:

Medium-ref ISO 8503. The tool works efficiently and provides an excellent surface for the subsequent paint system. Tool design gives good rounding of edges to existing intact coating. The paint system achieves good surface adhesion because of the excellent roughness profile.

QHES:

Low RPM and the teeth design of the abrasive tool provide minor breakage during grinding, corrosion or paint. This offers little dust problems. The tools have low vibration levels and give little vibration to the operator. Old paint is not warmed up to release dangerous fumes when it’s pretreated. The grinding tool is certified as cold work and gives no danger of explosion when working in explosion potential areas.

Statement by the operator after testing equipment:

The equipment works well. It does not create dust issues, and therefore respirator is not needed. The equipment provides low noise. The tool works efficiently and requires little force to remove paint and rust. The equipment is reliable and has no operational problems. We removed the thick coating effectively. Working faster with this tool.

Difficult access, some corrosion.

Different types of tools provide good access.

Here, a die grinder is in use.

The tool used on a flange.

The steel is clean and free of corrosion.

Efficient removal of old paint and corrosion.

CONCLUSION:

The tool provides qualitative, Safety related and productivity advantages,

compared with other similar equipment designed for mechanical pretreatment.

Result after applying the topcoat.