Cold work surface preparation – Weld seam removal

Safety Tools Allmet offers long-lasting, efficient tools for the job when you need cold-work-certified surface preparation tools. For both cutting and surface grinding preparation.

An example from Cold Pad was a job for doubler plate removal.

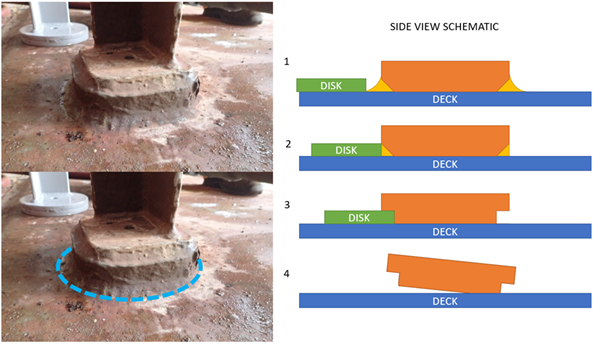

Firstly, a plan for removal with visuals for how to access the weld with the A-0503 disc. As a part of the A-0302 Weld removal kit.

Planning the removal of weld seam