Introduction

Non-Sparking tools solve a big problem for industries that work in explosive environments. For material removal jobs in Atex gas zone 1 and 2, you must guarantee that you can work with non-sparking tools. Otherwise, with hot working tools, you will need Habitats, fireguards, and more that we discuss later in this article. There is also the worst-case scenario which gets very expensive, very fast. And that is dangerous situations and production shutdown, words that no production manager wants to hear.

Cold work is defined by tools that do not generate high heat. Spot repair involves removing damaged or deteriorated parts of the coating and the associated contamination, followed by replacing a new coating. This helps to extend the life of the coating system with minimal intervention.

Spot repair

Spot repair maintenance on coatings is a constant process. As a fact, it is a necessity to ensure the coating system is performing optimally and protecting the underlying asset substrate.

Spot repair involves removing damaged or deteriorated parts of the coating and the associated contamination, followed by making a surface ready for the new coating. This helps to extend the life of the coating system with minimal intervention.

A more in-depth article about spot repair.

The size of the spot areas can be vastly different from each other, depending on location. When we talk about spot repair, we often size them as 5x5cm areas.

The reasoning behind this is that we can easily show the estimated lifetime of our grinding tools.

Spot repair – comparison

Spot grinding is where our handheld tools shine the most, instead of using large and heavy equipment and much personnel for a job. You can instead use one person and one air tool to do it.

Often we compare the direct costs when comparing grinding and abrasive blasting. One should also take the cost of TIME into effect. Often we hear the quote:

“Time is money”

Most people will agree with this statement. The time it takes to rig up, rig down, and clean the work area for a job is also a major factor. Cold working tools from Safety Tools Allmet take minutes to set up and are very efficient when performing spot repair.

We will never quote that one shouldn’t use abrasive blasting. On the contrary, one could use this type of surface treatment on huge areas. But when you have spots of rust/corrosion, one should instead consider using cold working tools that will not damage coating around the corroded area and make the surface ready for a new coating, while creating a smooth “feathered“(new tab) surface between the coating.

Another popular method for surface preparation

Ultra high-pressure water jetting (UHPWJ)

Cleaning with water can have the advantage over abrasive blast cleaning in that it does not require a clean-up operation of spent abrasives and has no abrasive cost. It will, however, make a mess of coating fragments and rust fragments spread out on a large area that needs cleaning/treatment afterward. It also makes the substrate wet, and corrosion starts immediately, and it will not create a new surface profile. This will additionally give fewer options when choosing new paint/coating.

UHPWJ Health and safety

Due to the extremely high pressure, up to 3000bar! The water at the cleaning nozzle presents a safety hazard for the operator and observer. Operators also need to add special armored PPE to their normal PPE when operating this equipment.

In addition to the above statements, one should also take the planning of operation in mind. The job should always be pre-planned when using Ultra high-pressure water jetting as the surface treatment tool. This is due to the major safety issues that you must recognize on the forehand.

Ultra-high pressure water jetting advantages and disadvantages

Advantages

- Removes salt and rust in one step.

- No dust is produced.

- No grid cost. (As compared to blasting)

Disadvantages

- Flash rusting. (new tab)

- Expensive and very heavy equipment.

- Less efficient compared to competitors.

- No surface roughness as it will only reveal the existing anchor pattern.

- Water quality and availability.

- Water freezes below 0°C.

- Specially trained personnel.

- Special PPE requirements.

- Mandatory resting and breaks.

Abrasive blasting vs Cold work tools from Safety Tools Allmet

Abrasive blast cleaning

The most common surface preparation method for large areas. The surface is cleaned by propelling abrasive particles at high speed towards the surface to be treated. The impact of the abrasive particles will remove rust, mill scale, and old coatings. Using abrasive blast cleaning, you also create a good surface profile.

Some typical limitations:

- Complex equipment. (PPE)

- Require more workers to operate.

- Pollution. (Dust, Heavy metals, etc.)

- Safety risk due to the high-velocity stream of abrasives.

- Do not remove oil.

- Do not remove salt.

- Used sand is classified as special waste in many places.

- Creates dust.

Cold work tools – Safety Tools Allmet

The grinding and cutting tools are almost entirely made of tungsten carbide. The discs and burrs lifetime last much longer than conventional grinding discs and burrs.

Non-sparking cold working tools from Safety Tools Allmet provide many HSE benefits such as;

- No hot sparks. It does not damage the substrate and underlying paint/coating.

- Low heat. Heat varies from 30 ℃ to 60 ℃ for grinding on steel. You can immediately place your hand on the steel, even after a long period of grinding.

- Low vibration. Tested and approved for use over a normal workday. 7.5 hours

When you use the cold working tools, the only requirement is standard PPE.

There is always limitation towards the tools that you use, here are the limitations of our cold working tools.

- High initial purchase price.

- Slower when used in huge areas, compared to abrasive blasting.

Cold work tools – Material aspects

There are many different types of steel and titanium, and these have different material propositions. There are no tools that can “do it all,” but we might be very close. Some of the most common steel types are carbon steel and stainless steel. We have listed an article with more information about steel here. (Opens in a new tab)

These are some of the most commonly used steel and titanium material types used in the oil and gas industry:

- Stainless steel Grade 316

- Steel ST52

- Titanium

- ASTM B265 Titanium

- Austenitic stainless steel

- 6MO

Surface preparation using Safety Tools Allmet

Grinding and cutting tools from Safety Tools Allmet is very efficient and competitive for use outside of dangerous areas. In addition to the great HSE benefits the tools provide.

No matter whether you use the tools in or outside gas zones, our grinding tools meet the SSPC-SP11 Surface Preparation Standard requirements.

The tool creates a good roughness profile of between 40-75 microns and has been tested independently for surface adhesion by many international companies.

This standard is suitable where a roughened, clean, bare metal surface free of all visible oil, grease, dirt, rust, coating, oxides, mill scale, corrosion products, and other foreign matter is required.

The peaks and valleys on the prepared surface form a continuous pattern with no smooth, unprofiled areas.

Using cold work tools in hazardous areas

Most of these materials are often used in the oil and gas industry for liquid and gas transportation. Refineries and FPSO’s that need maintenance needs to shut down their operations and create hot work areas when doing maintenance. There is a new competitor for performing work maintenance in these types of situations, and that is where the cold working tools from Safety Tools Allmet perform the best.

Cost comparison

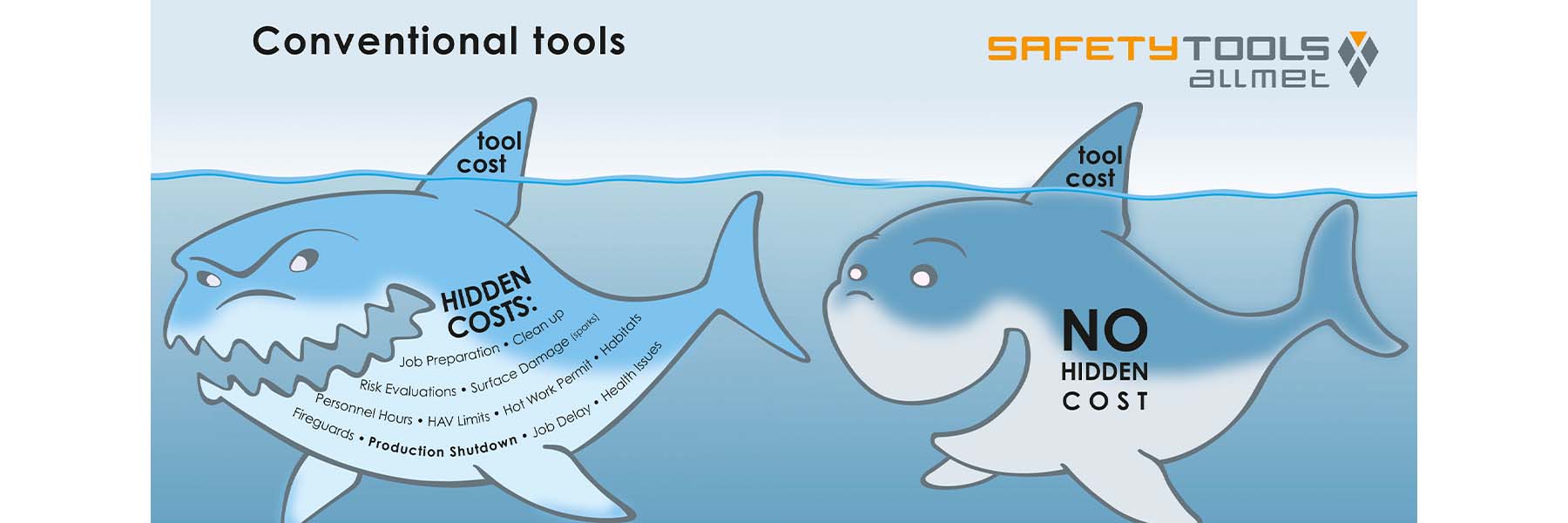

The picture says it all.

There is a huge difference directly related to cost when you compare conventional grinding and abrasive tools vs the Ex-certified, non-sparking, cold working tools from Safety Tools Allmet.

Initial tool purchase is a one-time expensive cost, but in the long run, this cost is nothing compared to the alternative.

Summary

So… What have we learned?

Well, looking back, we can read that Cold Working tools from Safety Tools Allmet shine the most when used for spot repair and in hazardous environments. More details for the tools:

- Ex certified for use in zone 1 & 2. No Hot work permits. Certified by DNV and it is classified as a Cold Working Tool.

- No hot sparks. Prevention of spot corrosion caused by conventional cutting and grinding.

- Low heat. The heat ranges from 30℃ to 60℃ for steel grinding. You can immediately place your hands on the steel, even after a long period of grinding or cutting.

- Low vibration. Tested and approved for subsequent use over a full working day. 7,5 hours

For the above pointers. There is no requirement for the use of habitats or fireguards. No need to covering of expensive equipment nearby. It is possible to work near your colleagues, improving productivity.

Our “Cool” technology is used in many sectors, including the oil and gas industry, the petrochemical industry, steel construction, and shipbuilding. As well as during maintenance work on bridges, offshore installations, and wind turbines.

There are some competitors in the industry, mainly the use of abrasive blasting. (new tab)