Dust explosions (ATEX)

What is an explosive atmosphere?

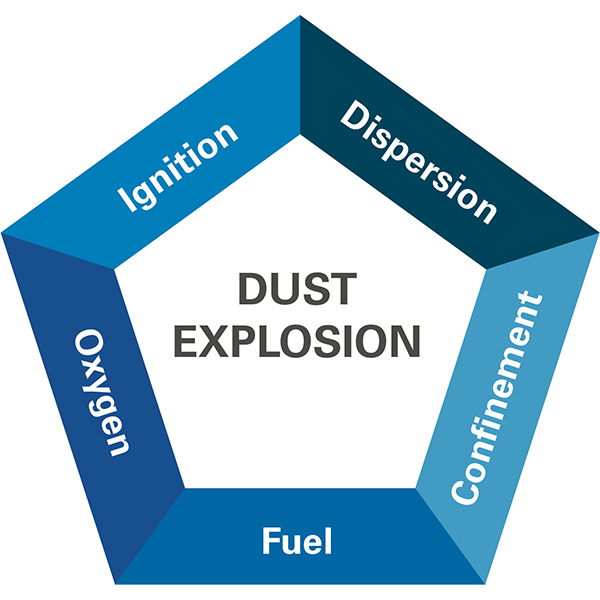

An explosive atmosphere is an accumulation of gas, liquid mist, dust, or vapour mixed with air in an explosive mixture and can ignite with an ignition source.

An explosive atmosphere does not always have to end in a pure explosion. If the explosive mixture ignites, the flames can spread quickly through the explosive atmosphere. Suppose this happens in a closed area, for example, in a processing plant or inside the equipment. In that case, the rapid spread and increase in pressure, among other things due to turbulence, could lead to the combustion increasing in speed and appearing like an explosion. The explosion pressure can also cause damage and flames from the combustion process.

Basic Technical Concepts

ATEX Dust zones

Dust zone 20

- An area in which an explosive dust atmosphere, in the form of a cloud of dust in the air, is present continuously, for long periods or frequently.

Dust zone 21

-

An area in which an explosive dust atmosphere, in the form of a cloud of dust in the air, is likely to occur in regular operation occasionally.

Dust zone 22

- An area in which an explosive dust atmosphere, in the form of a cloud of dust in the air, is not likely to occur in regular operation but, if it does happen, will persist for a short period only.

ATEX Gas zones

Gas zone 0

- An area in which an explosive gas atmosphere is present continuously, for long periods, or frequently.

Gas zone 1

- An area in which an explosive gas atmosphere is likely to occur periodically or occasionally in regular operation.

Gas zone 2

- An area in which an explosive gas atmosphere is not likely to occur in regular operation, but if it does, it will only exist for a short period.

Ignition sources

A dust explosion can be triggered by:

- Fire – open flames.

- smoldering fire.

- Auto-ignition in powder.

- In dust layers on hot surfaces.

- Mechanical sparks from friction in machine parts or from grinding.

- Electric sparks.

- Discharge by static electricity from plastic surfaces (pipes and containers), textiles, and equipment

You can find a lot of relevant information on the Norwegian labour inspection authority website↵.

Typical exposed areas

- Typical exposed areas

- Mills (Flour, grain, etc.)

- Conveyor belts

- Food production plant

- Coal mines

- Sawmills

- Silos

Simulation of dust explosion with flour.

Pictures – Creative Commons Attribution-Share Alike 3.0 – Hans-Peter Scholz

Requirements and certification

There are very high requirements for equipment that has been certified for use in both ATEX gas zones and ATEX dust zones. We are proud to have a 3-part ATEX certification for ATEX Gas Zones 1 and 2 and ATEX dust zones 21 and 22. You can use Safety Tools Allmet in all the previously mentioned typically exposed areas. The tools also generate no airborne dust during use. All fragments fall near your work area, and no surrounding equipment is not damaged. The removed fragments are easy to clean after finishing work, and the fragments are not sharp.