Efficient and Safe Maintenance of Tank Facilities for Petroleum Storage

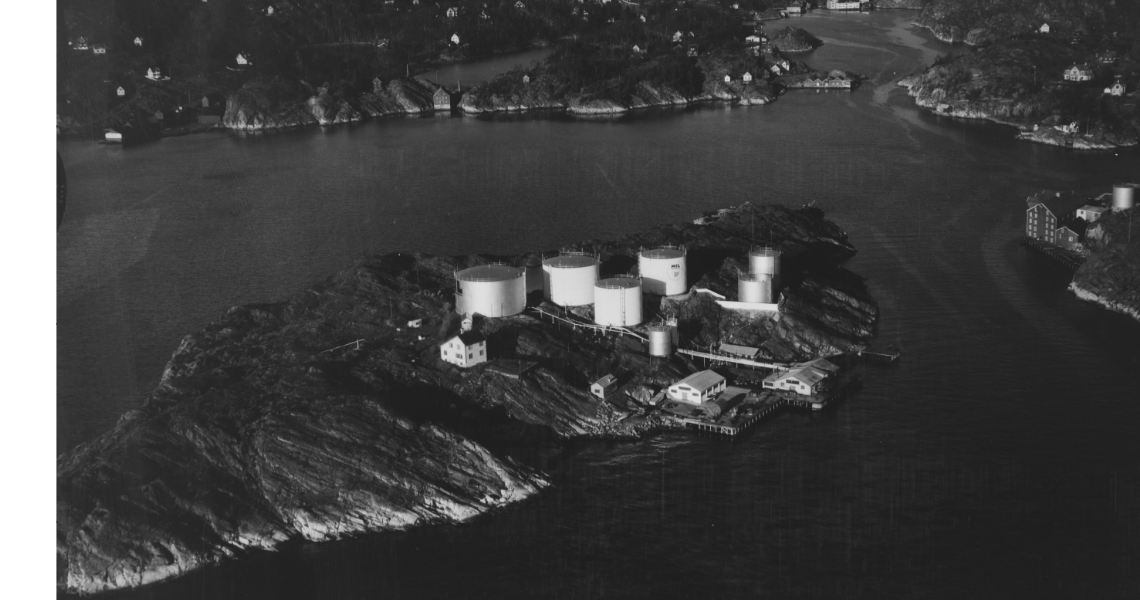

Safety Tools Allmet’s employees traveled to an island that has had active tank facilities for many years. These tank facilities, used for petroleum storage, play a critical role in energy supply and must therefore be maintained to the highest standards of safety and efficiency. Tank facilities for petroleum storage are designed to store large quantities of oil and other petroleum products in a safe and secure manner. Due to the dangers associated with handling such materials, strict safety measures are necessary to prevent accidents and environmental damage. It is worth noting that the operation of the facility had ceased at the time STA was on site, but this does not mean there is no risk of fires and explosions. Therefore, ATEX-certified grinding and cutting tools were used on site.

Such tank facilities have strict requirements for hot work as they are often divided into safety zones. There can be ATEX gas zones 1 or 2 at the facilities, where certified solutions are required for grinding and cutting operations.

Safety Tools Allmet has developed grinding and cutting equipment for use in ATEX gas zones 1 and 2. This makes it possible to avoid shutdowns, so that operations do not need to be stopped. The significant HSE (Health, Safety, and Environment) benefits are also important to consider.

What are ATEX Gas Zones and Why is ATEX Approved Equipment Important?

ATEX (Atmosphères Explosibles) gas zones are classifications used to identify areas where explosive atmospheres may occur. Gas zone 1 refers to areas where an explosive atmosphere is likely to occur in normal operation, while gas zone 2 refers to areas where an explosive atmosphere only occurs rarely and then only for short periods.

The use of ATEX-approved equipment in these zones is essential to prevent ignitions that could lead to serious explosions. ATEX-approved grinding and cutting equipment, such as that developed by Safety Tools Allmet, ensures that maintenance work can be carried out safely without risking accidents. This is especially important at tank facilities where continuous operation is critical, and shutdowns can lead to significant economic losses.

By using Safety Tools Allmet’s equipment, companies can maintain the safety and efficiency of their operations, even in the most challenging environments. This is an important step towards ensuring a stable and secure energy supply while safeguarding health, environment, and safety.

Reference: [Storholmen ved Askøy]. Avdeling for spesialsamlinger. Accessed: Fri Jun 14, 2024. Publisher: University of Bergen Library. Picture estimated from 1935-01-01 og 1939-12-31. The photo was taken before the bombing of Storholmen.

Reference: [Storholmen ved Askøy]. Avdeling for spesialsamlinger. Accessed: Fri Jun 14, 2024. Publisher: University of Bergen Library. The photo was taken before the bombing of Storholmen.

Maintenance of Steel Structures

Spot Repair

The size of spot repair areas can vary widely and are often spread over larger areas. When we talk about spot repair, we divide them into 5×5 cm areas to provide concrete lifespan and good estimates for different uses.

A-0008 Big Papa

Our grinding burr, A-0008 Big Papa, as shown in the video below, has an expected lifespan of 16,000 spots and creates an average surface roughness of 72μm (micrometers).

Cold Work

Cold Cutting Solutions

By using Ex certified cutting solutions, you can avoid the need for hot work permits and habitats. You can use cutting solutions in Ex zones where gas may be present without the dangers associated with hot work solutions. There is no need to set up habitats when using Safety Tools Allmet’s cold solutions. Simply connect to air and water, and start the work.

Safety Tools Allmet’s cold cutting solutions are highly durable. With an experienced user, the cutting disc can cut and mill approximately 12 meters in length and 8 to 12 mm deep. If you use a special solution such as the Cutting Guide Compact, Pendulum Arm, or Cutting Guide Jr, you will find that the lifespan of the cutting disc is significantly increased.

Storholmen

Safety Tools Allmet was fortunate to visit Storholmen, which is now decommissioned. Despite the facility being shut down, strict requirements for the use of correct and certified tools are still enforced.

If you wish to see earlier pictures from Storholmen, you can find them in UIB’s archive below, specifically related to the bombing of the island in 1940.

Other articles about cold work tools from Safety Tools Allmet:

Case Study: 2 Months Use on a Chemical Tanker

Over a two-month period, Safety Tools Allmet’s cold solutions were used on a chemical tanker for various maintenance tasks. The tools proved durable and efficient, handling numerous spot repairs and surface preparations. The results demonstrated the tools’ capability to maintain safety and performance standards in challenging marine environments.

Pipe Repair on an Offshore Platform

Using certified cold work tools from Safety Tools Allmet, pipe repairs on offshore platforms can be conducted safely and efficiently. These tools allow for maintenance in explosive atmospheres (Ex zones) without the need for hot work permits, reducing downtime and enhancing safety.

Case Study: Floating Oil Tank Inspection / Repair

Safety Tools Allmet’s cold solutions were utilized for the inspection and repair of a floating oil tank. The tools provided a clean, sandblasted-like surface that was ready for painting, ensuring excellent paint adhesion and long-lasting results. The use of cold work tools minimized the risk of fire and explosion, making the process safer and more efficient.

Spot Repair Maintenance – Do Conventional Grinding Discs Do More Harm Than Good?

Conventional grinding discs can generate sparks and dust, posing safety hazards and potential damage to surrounding equipment. In contrast, Safety Tools Allmet’s cold grinding solutions produce no airborne dust and generate fragments that are easy to clean up and do not damage equipment. This makes spot repairs safer and more effective.

Composite Repair

Composite repairs often require a clean and rough surface to ensure proper adhesion. Safety Tools Allmet’s tools can create the necessary surface profile without the hazards associated with traditional hot work methods. This makes them ideal for composite repair applications.

Recommended Usage Areas

Our cold technology is used in many sectors, including oil and gas, petrochemical, steel construction, and shipbuilding. In addition to maintenance work on bridges and offshore installations.

Below you can find our project pages.

Cold Solutions - ATEX Certified

Health, Safety & the Environment

Products comply with Health Safety & the Environment (HSE & OSHA) requirements, offering low vibration, heat, and noise levels. The fragments are large and blunt and will stay within a few centimetres/inches of your work area, thus making cleaning up simple and safe.

Certified and classified by Gexcon Certification

All solutions from Safety Tools Allmet are ATEX Certified as safe to use in ATEX Gas zones 1 & 2. Our cutting tools are also certified for use in ATEX dust zones 21 & 22. No need for a hot work permit, habitats, fire guards, shutdowns and nitrogen flushing/flushing.

Tungsten Carbide

Our rotating files and discs consist of solid tungsten carbide. The hardness and design of the teeth significantly increase the lifetime of the grinding files and discs. You can expect a lifetime of 100 times more than conventional burrs.

Spot Repair

Ex-certified cold work tools from Safety Tools Allmet provide a good, clean surface with a profile that meets the requirements of the SSPC-SP11 Surface Preparation Standard.

Surface profile

The solid tungsten head for Safety Tools cold rotating grinding files has different designs on its teeth so that they can produce different surface profiles for every situation. Our burrs create a roughness profile of between 40 – 75 microns.

Adhesion and Cleanliness

The correct surface profile creates a suitable anchor for paint and coatings. ATEX grinding tools from Safety Tools Allmet create good adhesion and a clean surface. Extensively independently tested for surface adhesion by International Paint, Jotun, Chevron and Weatherford.

NO Isocyanates - LOW Sound levels - LOW Vibration

NO release of isocyanates when grinding or cutting through polyurethane.

Low sound level. (<85 dB)

Low vibration. (Average <2.5 m/s)

Safety Tools Allmet - Since 1998

We are experts in training, usage and maintenance of our cold solutions. We can document years worth of good feedback from customers worldwide.