Case study by Perspect

On-site repair

During a tank inspection at a large refinery on Antwerp Scheldelaan, various leaks on a floating tank robbery emerged. They could not empty the tank before the repair, so a ‘live’ repair had to be carried out. Perspect↵ executed this project with the repair composites from Belzona and the ATEX/Ex-certified tools from Safety Tools Allmet.

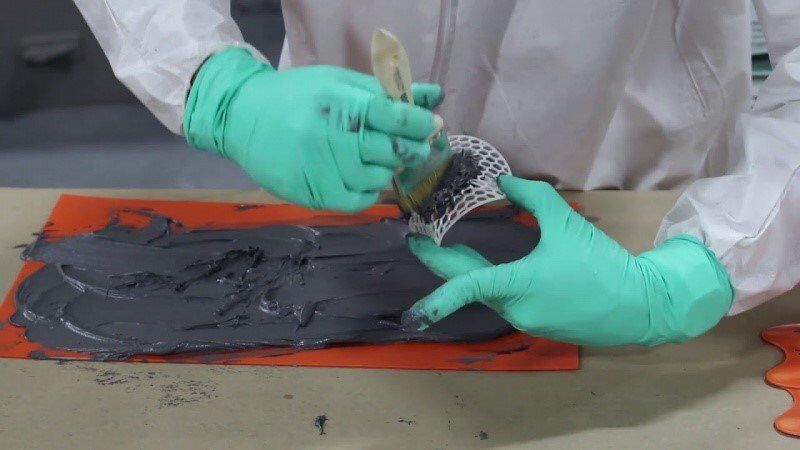

Innovative 3D mesh

First, the gap had to be closed. Belzona has the 3D mesh↵ in its range for sealing these types of leaks in problem areas. It has been specially developed to stop leaks effectively and easily. Given the live leakage, pre-treatment of the substrate was not possible.

Surface tolerant repair paste

It was decided to attach the 3D mesh with the Belzona 1212↵. The Belzona 1212 is ‘surface-tolerant’. It can be applied on (oil) contaminated surfaces with minimal roughening. By using this metal paste, the 3D Mesh was applied over the leak and the leak was finally closed.

Degrease With the Belzona 9111

After placing the 3D mesh, the problem areas could then be cleaned where possible with the Belzona 9111. This Belzona product has been specially developed to effectively degrease surfaces and equipment.

Grinding in ATEX zones

Tank inspection and treatment

After the leak has been closed, the situation changes from ATEX zone 0 to ATEX zone 1. Perspect could use the ATEX certified patented Safety Tools for this application. For this application, the Rotating grinding file A-0002 was used.

The patented non-sparking tools used for grinding, cutting and roughening consist of more than 95% tungsten carbide. And scores higher than 9.7 on the Rockwell hardness scale. The hardness is harder than a industrial diamond. The specially developed alloy offers unique properties and, among other things, extends the life of the non-sparking tool.

Belzona 2111 (Flexible coating)

A floating roof on an oil tank is constantly in motion. In order not to lose the flexibility due to the metal paste, a finish with the Belzona 2111↵ was chosen. The Belzona 2111 is an elastomer that is suitable for applications where durability, elasticity and high resistance are central. The application possibilities of this product are great. The product is also used for emergency repairs to conveyor belts and rubber linings.

Other articles:

Cold cutting – The new competitor

FPSO – Surface preparation and Digital Paint Report

Brand new ways of working with no production disruption in ATEX environments