Tested for 2 months

We have tested the equipment for approximately 2 months with various tasks onboard the oil/chemical tanker. The equipment has been performing exceptionally well, and we have compiled a report on our experience.

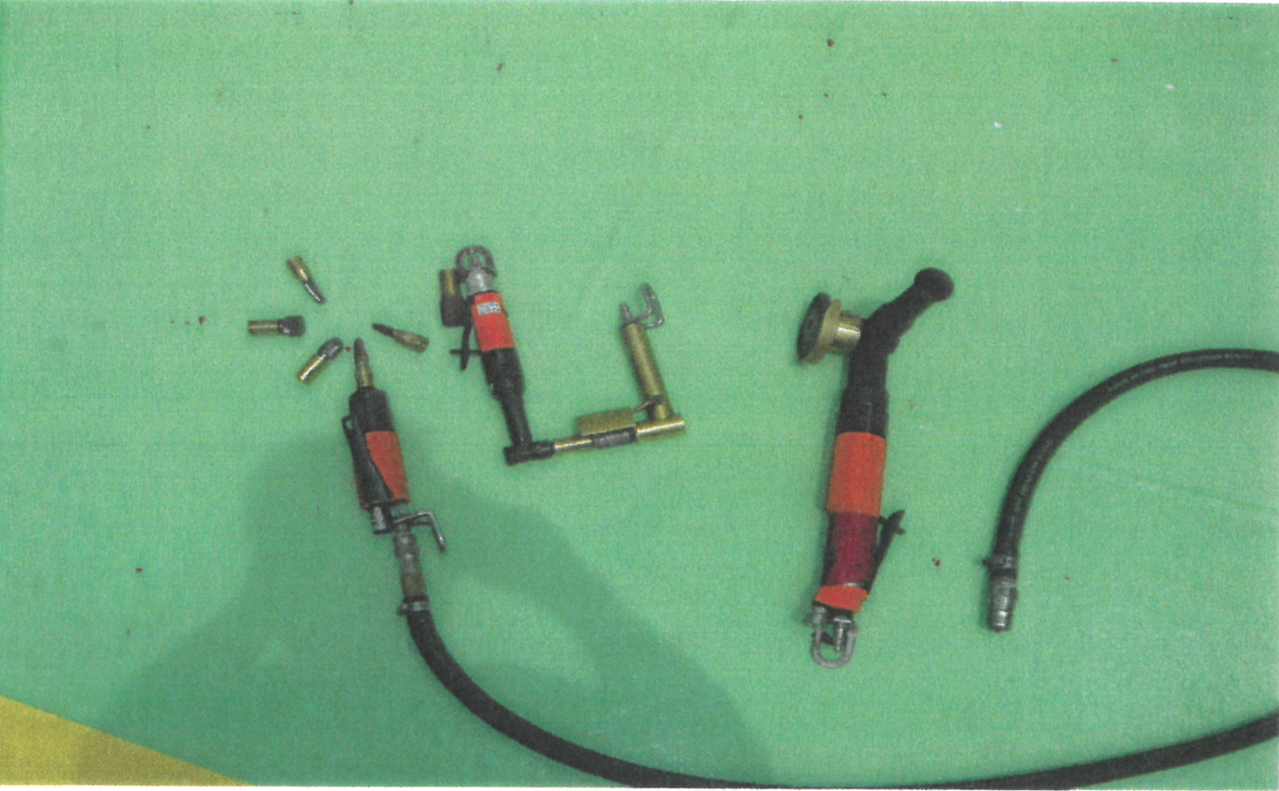

The tools worked very well, with their different designs and sizes making them convenient for use in most areas on deck. However, it was unfortunate to observe that the crew on deck initially had a negative attitude towards the new tools. This was mainly because these tools require slightly more physical effort compared to the previous «chipping hammers,» which operated automatically. After some discussions and meetings, the crew’s attitude became increasingly positive, especially as they saw the results.

It is crucial to provide proper instructions to the crew regarding the use of these tools due to their efficiency. If not used carefully, they can easily remove a significant portion of the steel thickness along with the rust. In some instances, when dealing with severely rusted areas, it can be challenging to remove all the rust without going too deep into the steel. In such cases, we found the absence of a flexible rotating steel brush (or something similar) to be a limitation.

The tools are very convenient for use on deck, particularly around clamps and in corners with difficult access. Additionally, the grinding machine is excellent for removing old paint and rounding edges before painting begins.

Crack in paint

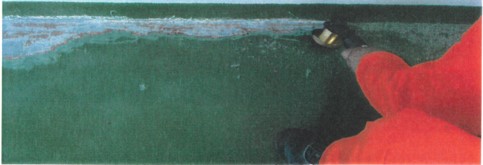

Removing Paint and Rust Using Safety Tools Allmet

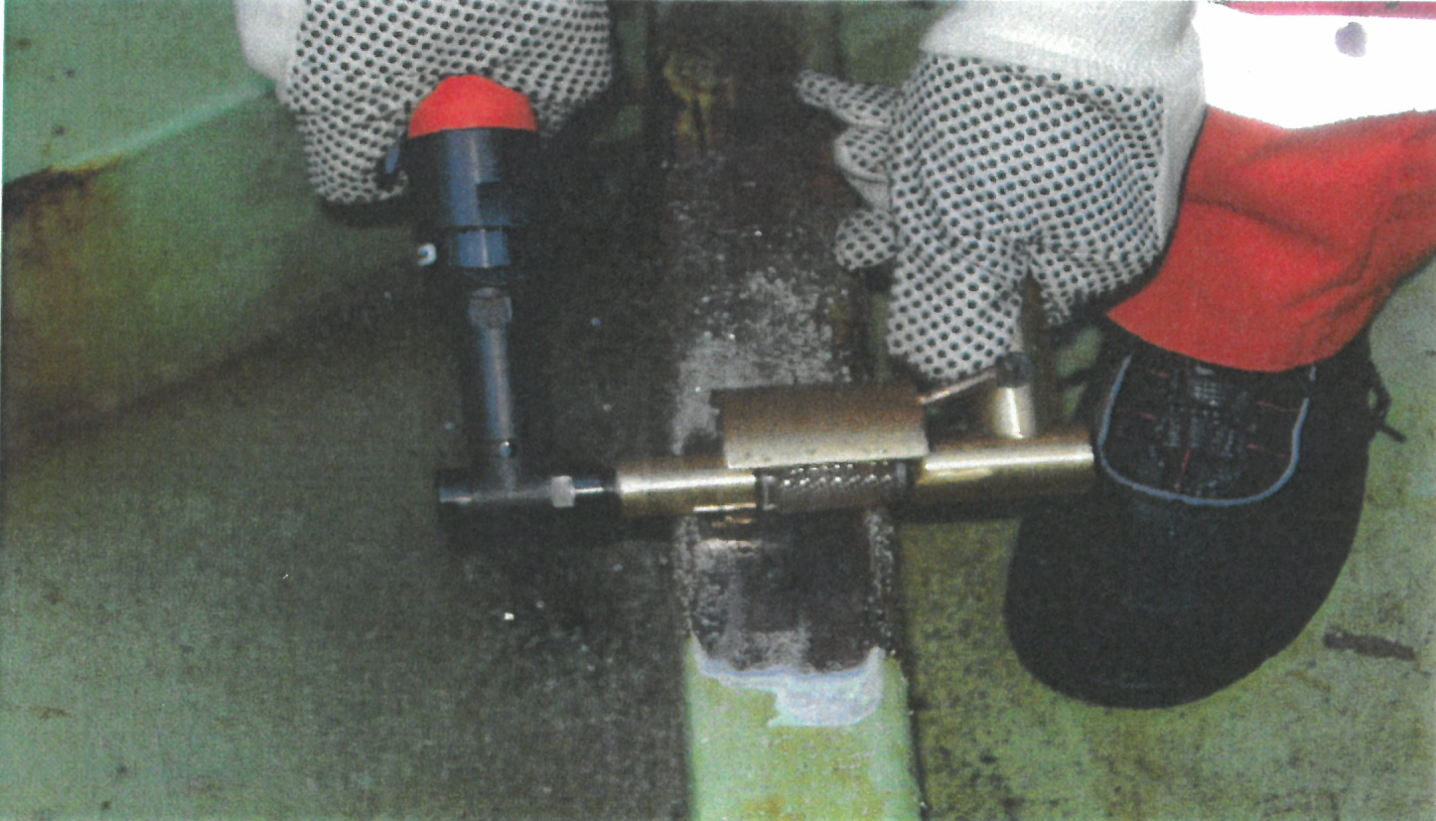

Tight areas

Paint flaking

Many advantages

Rust removal

Best burr

In progress with the best choice of tools. The A-0003 burr was perfect here.

Clam on chemical tanker

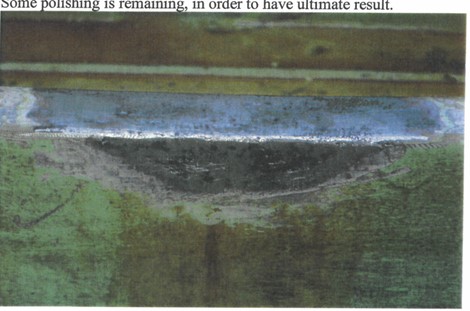

Picture of same clam, after some of the rust has been removed. Some polishing remains.

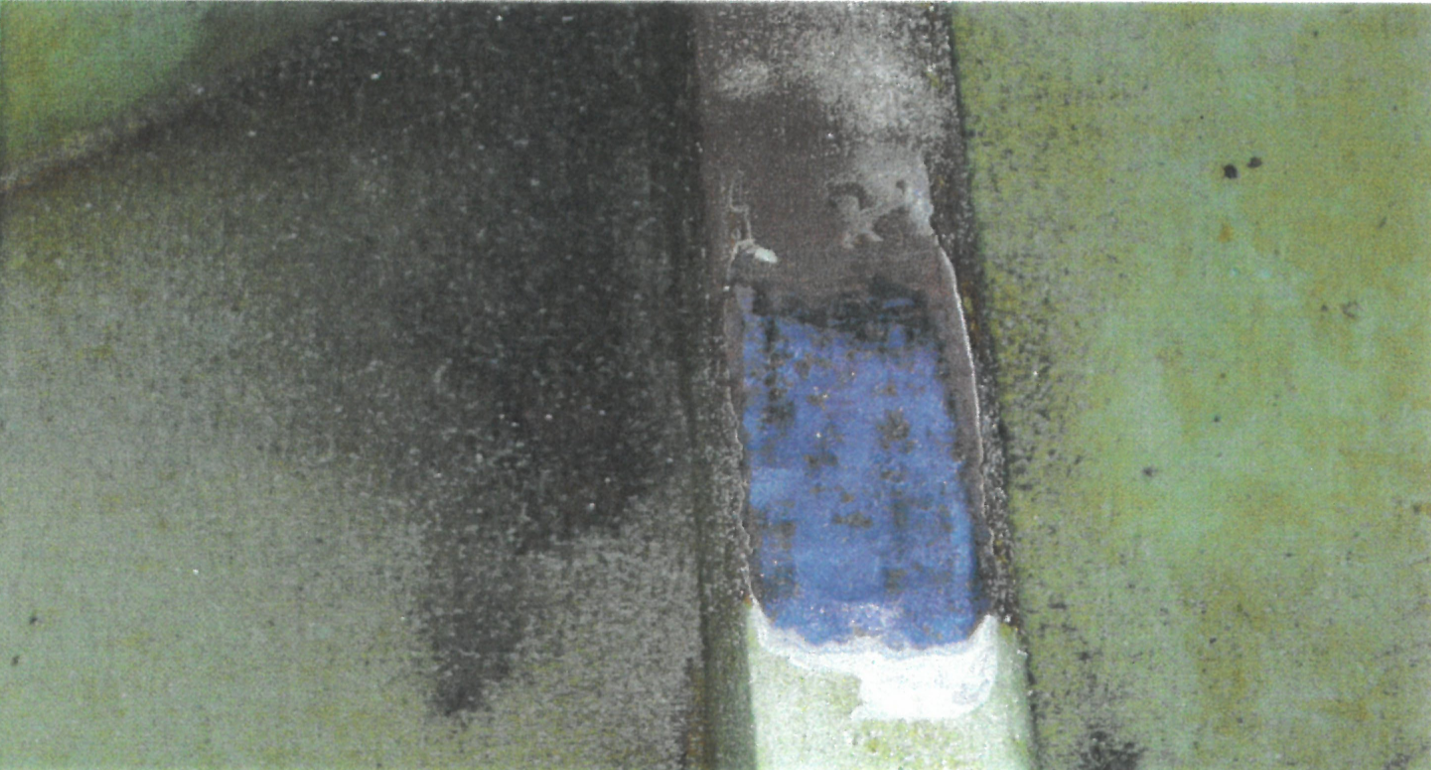

Heavy rust

In progress…

The result..

Continuation

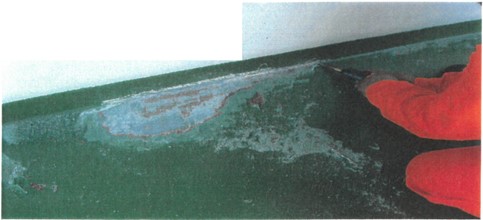

Precision grinding

The tool does not require pressure from the operator, easy to choose how much paint to remove in order to not create deep craters in the steel.

END OF CASE STUDY.

So, why should you choose Safety Tools Allmet?

Our grinding and cutting tools are Ex-certified by Gexcon Certification as Cold Work for use in Gas zones 1 and 2.

In addition to the numerous HSE advantages, there are also many cost-effective advantages, such as;

- No need for Hot Work Permit – Due to Ex-certification.

- Use less time on risk evaluations – Due to Cold Work certification.

- Avoids postponements – You can use the tool safely, so you do not have to postpone jobs.

- No need for Habitats – You will not ignite gas or damage equipment around you.

- No need for fireguards – No ignition of Natural gas.

- Avoid production stops/delays.

The statements above are accomplished by reducing heat, noise, and vibration. This creates a safer working environment where you save lives, protect human health, and save money.

- No Hearing injuries – Noise <85 dB

- No “White fingers” – Vibration Level <2,5 ms²

- No Toxic damage – no release of isocyanides when grinding through the polyurethane

- No Fire Injuries

- No Explosion accidents – Temperature <70°

Grinding solutions

Alle produkter

Slipeløsninger

Alle produkter

Alle produkter

Alle produkter

Alle produkter

Alle produkter

Alle produkter

Alle produkter

Alle produkter

Alle produkter

thoroughly 3-rd party tested

- Det Norske Veritas (DNV) / (2024) Gexcon Certification – For use in hazardous gas zones 1 and 2

- Gexcon – Explosions tests

- ATR – Vibration

- Mutliconsult – Noise tests

- Jotun and DNV – Adhesion tests for Coatings

- Products are rigorously tested in the field – under the most demanding conditions!

The tools are easy to use, and you will always get professional results. But do not take our word for it!