Oil platform

“The equipment provides low noise. The tool works quickly and requires little force to remove paint and rust. The equipment is reliable and has no operational problems. We removed the thick coating effectively and worked faster with this tool.”

Applications on Offshore Platforms

Our mechanical surface preparation tool is used daily on offshore platforms around the world – both inside and outside ATEX gas zones 1 and 2.

The tool is designed for maximum flexibility and is well suited for a wide range of tasks in demanding offshore environments.

With virtually no limitations in its scope of application, the tool is used for, among other things:

Structural and Technical Areas

Drill floor and derrick

Helideck

Ladders, pipe racks, and support structures

Storage areas and wellheads

Mechanical and Rotating Systems

Winch and hoisting systems

Pump systems and pump rooms

Pipes and flanges

Inspection and Testing

NDT (Non-Destructive Testing)

DT (Destructive Testing)

Weld inspection preparation

Old weld removal

Tank and Vessel Work

Process tanks

Closed and open storage tanks

Internal tank maintenance

Coating removal

Transocean Leader 2012

Excerpt from: Case Study – Use of Safety Tools Allmet Abrasives

Experiences from work performed using Safety Tools Allmet

Work Execution

The rigging process was simple and efficient – only compressed air hoses needed to be connected to the tool.

The entire job was completed in less time than expected, thanks to the tool’s superior performance compared to conventional mechanical surface preparation methods such as flap discs, needle scalers, and similar equipment.

The tool exhibited very low wear during use and required no replacement throughout the project. This contributed to stable operation and reduced maintenance needs.

Economic Benefits

The high efficiency and reduced working time translated directly into cost savings for the project.

The grinding files are made from specially hardened steel and maintain a long service life, even under demanding conditions.

The machines are robust, designed for industrial use, and built to withstand continuous operation over time.

At the end of the project, the grinding tool remained in excellent condition and was ready for reuse on future jobs – further reinforcing the cost-effectiveness of this method.

Health, Safety and Environment (HSE)

The tool operates at low rotational speed and features a specially designed tooth that minimizes friction during grinding. This results in no airborn dust – and in most cases, there is no need for a filter mask. This contributes to a safer working environment and reduces the need for personal protective equipment.

The machines are engineered with effective vibration damping, ensuring low operator exposure even during extended use.

Because the tool generates low heat during operation, it prevents the heating of old coatings – reducing the risk of releasing hazardous fumes during surface preparation.

The grinding tool is certified as cold work and is therefore safe to use in explosive environments (ATEX zones).

This eliminates the need for hot work permits and provides greater flexibility in projects with strict safety requirements.

Always follow local regulations for PPE and QHSE.

Quality:

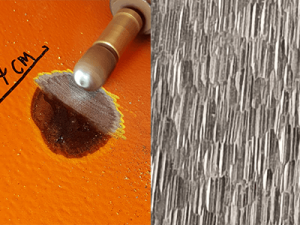

The tool provides cleanliness and roughness following the requirements per NORSOK M 501. Clean: St 3 / Sa 2 ½ ref ISO 8501-1.

Roughness:

Medium-ref ISO 8503. The tool works efficiently and provides an excellent surface for the subsequent paint system. Tool design gives good rounding of edges to existing intact coating. The paint system achieves good surface adhesion because of the excellent roughness profile.

Operator Statement After Field Testing

“The equipment performs very well. It produces no dust, so a dust mask was not necessary.

Noise levels are low,and only minimal effort is needed to remove both paint and rust.

The tool proved to be highly reliable, and we experienced no technical issues during use.

Thick layers of paint were removed effectively, and the work progressed faster than with previous methods.”

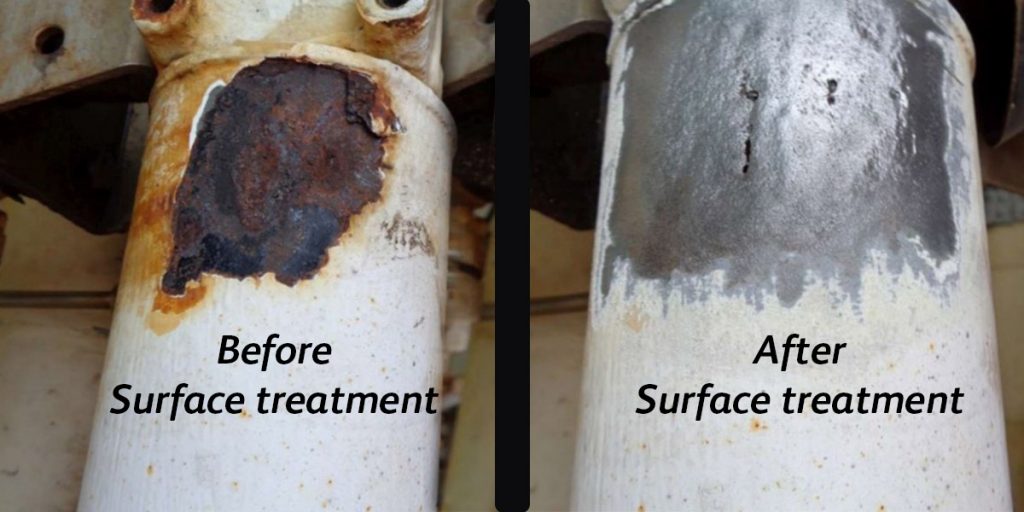

Pipe Repair on an Offshore Platform

A leak was identified in a pipeline at a major offshore installation in the North Sea, located within the Benelux region. The affected area was situated in an ATEX-classified zone, which required a strictly cold work approach for all repair activities.

To ensure proper surface preparation, the A-0004 “Little Papa” rotating file was selected. This tool delivers an average surface profile of 83 μm, which matched the exact specification required for the chosen repair materials.

The entire repair process was carried out as a completely cold solution—eliminating the need for welding or traditional hot surface preparation. The leak-sealing team operated exclusively with EX-certified Safety Tools Allmet equipment, ensuring full compliance with safety regulations in explosive atmospheres.

Thanks to this cold work method:

-No hot work permits were needed

-No risk assessments or habitat installations were required

-There were no job delays or standby time

-No fireguards were necessary

-No hot sparks or heat generation occurred

– No release of harmful isocyanates was detected

This project showcases the efficiency and safety advantages of using certified cold work tools in critical offshore environments.

Read the entire case study here: Case study: Pipe repair on an offshore platform.