Paint blistering

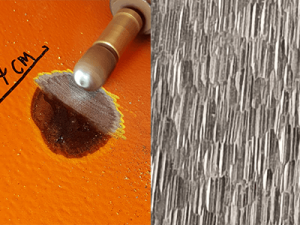

Improper surface treatment and improper use of pre-treatment tools can be several causes of paint blistering.

Paint blistering

Improper surface treatment and improper use of pre-treatment tools can be several causes of paint blistering.

Paint blistering refers to the formation of bubbles or blisters on the surface of painted materials. It occurs when there is a loss of adhesion between the paint film and the underlying surface or between paint layers. Blistering can be caused by various factors, including:

Moisture is one of the most common causes of paint blistering is moisture penetration. If moisture gets trapped beneath the paint film or enters through cracks or gaps in the substrate, it can lead to the formation of blisters as the moisture tries to escape.

Heat and humidity. High temperatures and excessive humidity can accelerate moisture vaporization, causing pressure to build up beneath the paint film and resulting in blistering.

Poor surface preparation: Inadequate cleaning, improper priming, or failure to remove contaminants from the surface before painting can prevent proper adhesion, leading to paint blistering over time.

Using incompatible or mismatched paint products, such as applying oil-based paint over a latex-based primer or vice versa, can cause adhesion issues and eventually lead to blistering. Applying paint too thickly, using low-quality or expired paint, or painting under unfavorable environmental conditions can all contribute to blistering.

Proper surface preparation is essential for achieving good adhesion between the paint and the substrate.

How to Prevent Blistering in Coating Systems

To avoid blistering and defects in paint and coating systems, it is essential to follow a carefully controlled process with attention to the following key factors:

Proper surface preparation

Remove all contaminants such as salts, oil, grease, and rust. Use appropriate methods such as mechanical grinding, water-based degreasers, or explosion-safe grinding tools for work in Ex zones.

Ensure the correct surface profile according to the coating type (e.g., an Rz value of 50–100 µm for epoxy systems).

Pre-treatment tools for ATEX gas zones

By using the right pre-treatment tool, you can prevent and avoid paint blistering.

Our cold solutions come with many benefits, including the following:

-

- No need for Hot Work Permit – Due to Ex-certification.

- Use less time on risk evaluations – Due to Cold Work certification.

- Avoids postponements – As you can use the tool safely, you do not have to postpone jobs.

- No need for Habitats – You will not ignite gas or damage equipment around you.

- No need for fireguards – No ignition of Natural gas.

- Avoid production stops/delays.

The statements above are accomplished by reducing heat, noise, and vibration. Which creates a safer working environment where you potentially save lives, protect human health, and save money.

-

- No Hearing injuries – Noise <85 dB

- No “White fingers” – Vibration Level <2,5 ms²

- No Toxic damage – no release of isocyanides when grinding through the polyurethane

- No Fire Injuries

- No Explosion accidents – Temperature <70°