Mechanical pretreatment and corrosion maintenance. We offer ATEX-certified grinding and cutting solutions for use in many different areas.

Corrosion Maintenance – Steel and Titan

Mechanical pre-treatment and corrosion maintenance are our specialties. We offer ATEX-certified grinding and cutting solutions with many different application areas and are already known for their high efficiency and long life.

Safety Tools Allmet has for over 24 years delivered ATEX grinding and cutting tools perfect for mechanical grinding, cutting, preparation, and repair work within the surface treatment.

Corrosion maintenance – pipe

Cold solutions

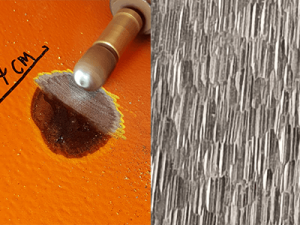

Our cold solutions provide a surface profile that corresponds to and resembles a sandblasted surface under ST 2.5 – 3. The result allows you to paint directly on a prepared surface and get good paint adhesion. Tests done by several paint manufacturers show optimal adhesion results.

The tool generates no airborne dust; all fragments fall where you work. Ensuring that the surrounding equipment is not damaged.

The fragments are blunt and can easily be removed after finishing or during the task.