Safety Tools Allmet grinding and cutting tools have been used and can be used in many different situations and areas. Such as the floating roof of an oil tank.

Grinding and cutting on the roof of oil tanks

Safety Tools Allmet grinding and cutting tools have been used and can be used in many different situations and areas.

Avoiding production shutdown is one of our most important selling points; with Safety Tools Allmet, you can safely perform grinding and cutting jobs in ATEX gas zones one and two.

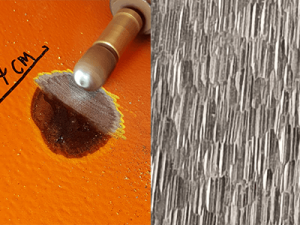

Mechanical pre-treatment on a floating roof on an oil tank.

Our grinding and cutting tools are Ex-certified by DNV as Cold Work for use in Gas zones 1 and 2.

In addition to the numerous HSE advantages, there are also many cost-effective advantages, such as;

- No need for Hot Work Permit – Due to Ex-certification.

- Use less time on risk evaluations – Due to Cold Work certification.

- Avoids postponements – As you can use the tool safely, you do not have to postpone jobs.

- No need for Habitats – You will not ignite gas or damage equipment around you.

- No need for fireguards – No ignition of Natural gas.

- Avoid production stops/delays.

During a tank inspection at a large refinery on Antwerp Scheldelaan, various leaks on a floating tank emerged. The tank could not be emptied before the repair, so a live repair had to be done. Perspect executed this project with the repair composites from Belzona and the ATEX/Ex-certified tools from Safety Tools Allmet.