FPSO’s Steel hull structures and tanks are often exposed to seawater and the marine environment.

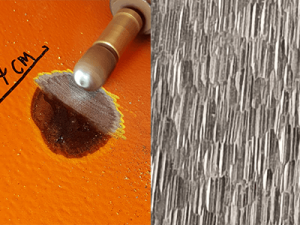

Mechanical pretreatment tools – FPSO

FPSO – “Floating Production, Storage and Offloading.”

Grinding and cutting tools from Safety Tools Allmet are used on FPSO / FSO worldwide.

Pretreatment of various surfaces on FPSO

Shared by our partner in the UAE↵.

FPSO – Typical problem areas

FPSO’s Steel hull structures and tanks are often exposed to seawater and the marine environment. They are most susceptible to corrosion and are often the primary concern regarding corrosion. But it is also essential to focus on external areas such as decks and superstructures.

The options for surface pretreatment are plentiful, and some have been around for a long time. There is no perfect universal tool for every situation, and you should always consider different tools depending on the job. Regarding an FPSO, You must treat EX zones with ATEX-certified tools for the job.

Cold work option for FPSO

Ex-certified cold working surface preparation tools from Safety Tools Allmet give a good clean surface with a profile meeting the SSPC-SP11 Surface Preparation Standard requirements.

- Ex-certified for use in zone 1 & 2. No Hot work permits. Certified by DNV and it is classified as a Cold Working Tool.

- No hot sparks. Prevention of spot corrosion caused by conventional cutting and grinding.

- Low heat. The heat ranges from 30℃ to 60℃ for steel grinding. You can immediately place your hands on the steel, even after a long period of grinding or cutting.

- Low vibration. Tested and approved for subsequent use over a full working day. 7,5 hours

In addition to the pointers above, there is no requirement for using habitats or fireguards. There is no need to cover expensive equipment. It is possible to work near your colleagues, thus improving productivity.