Composites can perform repairs with no disruption to operations. More and more pipeline operators are making these systems part of their pipeline integrity programs for repairing corrosion, dents, and other defects in their steel-piping systems.

Wrapping industry

Composite technology has been around for over a decade, representing an affordable and timesaving option for pipe rehabilitation. The introduction of codes and standards, ASME↵ and ISO ↵engineering standards, has helped composite repairs gain broader acceptance in the industry as an effective solution for restoring pipeline integrity and structural strength.

Composites can perform repairs with no disruption to operations. More and more pipeline operators are making these systems part of their pipeline integrity programs for repairing corrosion, dents, and other defects in their steel-piping systems.

Introduction to Composite Repairs (Wrapping)

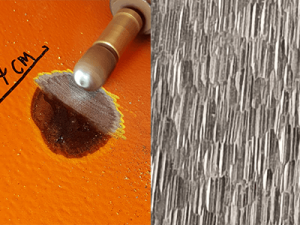

We have extensive experience with pre-treatment for various wrapping / composite products. Especially in Asia and the Netherlands, we see that the market for Wrapping / Composite is large, but there was a lack of suitable pretreatment methods. We made our special A-0052 – Wrap Solution kit, which is used worldwide today: for pipe wrapping, pipe support reinforcement, and general surface maintenance. The Solution contains the tools for almost any wrapping pre-treatment work.