“No tool can “do everything”, but we are very close to such a tool.”

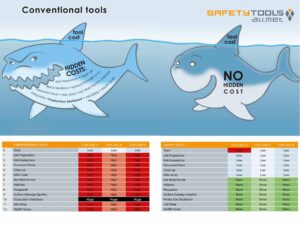

Minimize Maintenance Costs and Maximize Safety

Introducing non-sparking ATEX certified tools, groundbreaking solutions for industries operating in explosive environments. In Atex gas zones 1 and 2, the removal of materials can be safely accomplished without the need for habitats, firefighters, or other complex measures. By utilizing ATEX-certified tools, The implementation of ATEX-certified tools minimizes the likelihood of production stoppages, due to the ability to perform maintenance tasks while the production is LIVE.

Dont stop production, just take your safety tool and to the job.

ATEX certified tools from Safety Tools Allmet offer many HSE benefits, and not least:

-

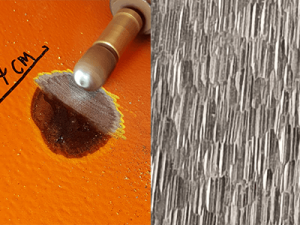

- No hot sparks. No damage to the substrate and underlying paint/coating.

- Low heat. Heat varies from 30 ℃ to 60 ℃ for grinding on steel. You can immediately place the palm of your hand on the steel. Even after a long period of grinding.

- Low vibration. Tested and approved for use over an entire working day. 7.5 hours.

Experience Optimal Safety with Safety Tools Allmet

When using tools from Safety Tools Allmet, the requirement is standard PPE.

There are many different material types of steel and titanium. No tool can “do everything”, but we are very close to such a tool. Some of the most common types of steel are carbon steel and stainless steel.

We have ATEX certified tools for both grinding and cutting on the following materials:

Cutting tools:

- Stainless steel grades 304/316

- Carbon steels

- Titanium

- 6Mo stainless steel

Grinding tools:

- Stainless steel grades 304/316

- Carbon steels

- Titanium

- 6Mo stainless steel

- Aluminium

Mechanical maintenance

After grinding with our tools, the result follows the SSPC SP-11 surface treatment standard.

The tool creates a good roughness profile of 40-75 µm (micrometres) and has been tested independently for surface adhesion by many international companies.

The term mechanical maintenance can be grinding away large amounts of steel. This is done efficiently using our cold ATEX solutions such as A-0058 – Steel Grinding solution. Or A-0057 – All Around with Rough Boy Solution.

By using Safety Tools Allmet's Steel Grinding Suitcase we completed the job in half the time conventional methods would have taken. In the process this saved circa £ 300 000 in costs.

The work went really well with very low noise and very little vibration. We are all in all very satisfied with the tools - we saved about a week's worth of work.

The Safety Tools Allmet grinding tools were tested under anticipated worst case conditions - operation within explosive mixtures of propane and acetylene. It was not found possible to provoke ignition of the explosive mixtures during any of the tests performed.

Statoil UPN safety delegate services will continue its effort to get the tool implemented in all our facilities where it is performed maintenance and modification work in areas that are pressurized and in operation.