Flash corrosion

Occurs after a few minutes to a few hours after cleaning is done

What is Flash corrosion?

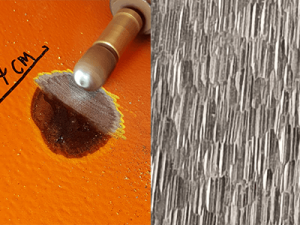

Flash corrosion occurs on steel from a few minutes to a few hours after cleaning, often using ultra-high-pressure water jetting (UHPWJ). Flash corrosion occurs quickly, primarily when water films reside on the steel surface, as it often does with conventional UHPWJ.

Corrosionpedia has a more detailed explanation here.↵

Ultra-high pressure water jetting advantages and disadvantages

Advantages

- Removes salt and rust in one step.

- No dust is produced.

- There is no grid cost. (As compared to blasting)

Disadvantages

- Flash rusting.

- Expensive and very heavy equipment.

- Less efficient compared to competitors.

- There is no surface roughness, as it will only reveal the existing anchor pattern.

- Water quality and availability.

- Water freezes below 0°C.

- Specially trained personnel.

- Special PPE requirements.

- Mandatory resting and breaks.

The alternative tools for avoiding Flash corrosion

Non-sparking cold working tools from Safety Tools Allmet provide many HSE benefits, such as;

- No hot sparks. It does not damage the substrate and underlying paint/coating.

- Ex-certified for use in zones 1 & 2. No Hot work permits.

- Low heat. Heat varies from 30 ℃ to 60 ℃ for grinding on steel. You can immediately place your hand on the steel, even after a long period of grinding.

- Low vibration. Tested and approved for use over a typical workday. 7.5 hours

When you use cold working tools, the only requirement is standard PPE.

For the above pointers. There is no requirement for the use of habitats or fireguards. There is no need to cover expensive equipment nearby. It is possible to work near your colleagues, improving productivity.

Our “Cool” technology is used in many sectors, including oil and gas, petrochemicals, steel construction, and shipbuilding. As well as during maintenance work on bridges, offshore installations, and wind turbines.