Rope access

Working in demanding heights and positions creates specific demands for the work equipment used. Good job pre-planning is essential.

Rope Access and Risk-Reducing Tool Selection

Work within rope access involves physically demanding tasks at height, often under challenging conditions where safety and efficiency must be carefully balanced. Grinding and cutting operations are particularly high-risk activities in these environments, and conventional high-speed tools (often operating at 10,000–15,000 RPM) pose several hazards:

– spark generation,

– heat build-up,

– sharp fragment projection,

– and increased vibration exposure.

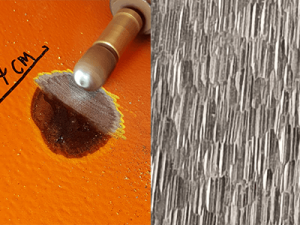

Low-Speed Tools with ATEX Certification

Safety Tools Allmet provides grinding and cutting tools specifically developed for use in explosive atmospheres and challenging working positions. With operating speeds between 1,000 and 3,000 RPM and a design that completely eliminates sparks, these tools offer substantial risk reduction. All units are certified for use in ATEX gas zones 1 and 2 and come with full certification documentation.

Proven Benefits for Rope Access Technicians

Based on feedback from experienced rope access professionals, several key advantages stand out:

-

Lightweight and ergonomic – ideal for work while suspended or in awkward positions.

-

Low noise and vibration levels – helps reduce long-term exposure and fatigue.

-

No heat or spark production – essential for work in explosive or flammable environments.

-

No sharp debris or fragments – minimizes the risk of personal injury or equipment damage.

Drop Safety System

For height-based operations, our tools can be equipped with a custom drop safety device, preventing accidental drops in case of mishandling or tool slips. This provides an additional layer of safety for both personnel and equipment below the work area, making the system ideal for use on scaffolding, rope, or offshore modules.