Some key advantages of Rough Boy Solution

By using ATEX-certified tools from Safety Tools Allmet, you will reduce time spent on demanding risk assessments and cut all costs related to shutdowns, fireguards, hot work permits, habitats, and demanding cleanup work. Rough Boy Solution contains our best file for surface treatment.

The air tools, grinding files, and grinding discs are Ex-certified as safe to use in ATEX gas zones 1 and 2↵ and ATEX dust zones 21 and 22.

Based on a surface treatment test performed at Safety Tools Allmet, Rough Boy grinding file removed 490 μm of oil based paint from 1 m² in 49 minutes.

A-0056 – Rough Boy Solution contains:

| Weight | 5.5 kg |

|---|---|

| Dimensions | 43 × 35 × 19 cm |

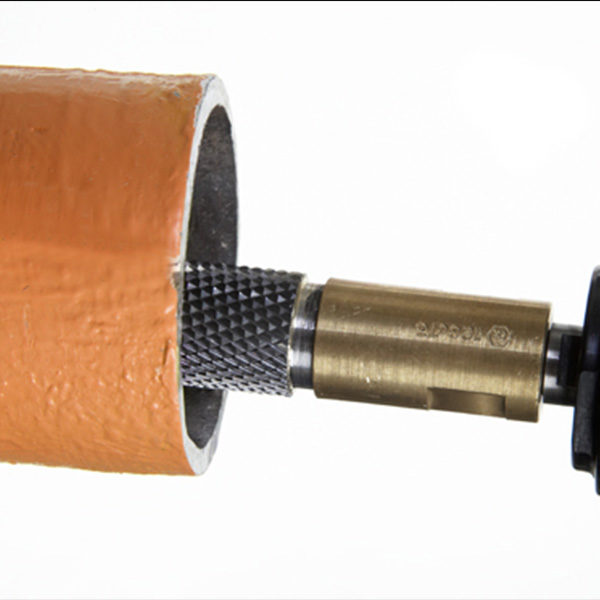

A-0010 – Rough boy – Life expectancy of 32,000 Spot (5x5cm)

Creates an average surface roughness of 45μm (Micrometers)

ATEX certificate

EC Declaration

User manual

Quality control checklist

Parts lists for air tools

Risk analysis for air tools

Ex-tools and accessories

The total lifetime of this solution’s grinding files and disks is 32 000 spots. (5×5 cm)*

You find the individual lifetime of grinding files and disks in the listing above and the surface roughness µm. (Micrometer)

Calculate your costs with our spot calculator.

*Lifetime depends on material type and coating/paint.

Health, Safety & the Environment

Our grinding products are designed to comply with Health Safety & the Environment (HSE & OSHA) requirements, offering low vibration, low heat, and low noise levels. The fragments produced are large, blunt, and will stay within a few centimeters/inches of your work area. This makes cleaning up simple and safe.

Long-lasting

Safety Tools Allmet rotating grinding burrs and discs have a long lifespan and consist of solid tungsten carbide, which gives our burrs and discs a material property harder than an industrial diamond. The lifespan of the rotating grinding burrs and discs depends on the application, but generally, they last hundreds of times longer than conventional alternatives.

Recommended Usage Areas

Our cold technology is used in many sectors, including oil and gas, petrochemical, steel construction, and shipbuilding. In addition to maintenance work on bridges and offshore installations.

Below you can find our project pages.

Cold Solutions - ATEX Certified

Health, Safety & the Environment

Products comply with Health Safety & the Environment (HSE & OSHA) requirements, offering low vibration, heat, and noise levels. The fragments are large and blunt and will stay within a few centimetres/inches of your work area, thus making cleaning up simple and safe.

Certified and classified by Gexcon Certification

All solutions from Safety Tools Allmet are ATEX Certified as safe to use in ATEX Gas zones 1 & 2. Our cutting tools are also certified for use in ATEX dust zones 21 & 22. No need for a hot work permit, habitats, fire guards, shutdowns and nitrogen flushing/flushing.

Tungsten Carbide

Our rotating files and discs consist of solid tungsten carbide. The hardness and design of the teeth significantly increase the lifetime of the grinding files and discs. You can expect a lifetime of 100 times more than conventional burrs.

Spot Repair

Ex-certified cold work tools from Safety Tools Allmet provide a good, clean surface with a profile that meets the requirements of the SSPC-SP11 Surface Preparation Standard.

Surface profile

The solid tungsten head for Safety Tools cold rotating grinding files has different designs on its teeth so that they can produce different surface profiles for every situation. Our burrs create a roughness profile of between 40 – 75 microns.

Adhesion and Cleanliness

The correct surface profile creates a suitable anchor for paint and coatings. ATEX grinding tools from Safety Tools Allmet create good adhesion and a clean surface. Extensively independently tested for surface adhesion by International Paint, Jotun, Chevron and Weatherford.

NO Isocyanates - LOW Sound levels - LOW Vibration

NO release of isocyanates when grinding or cutting through polyurethane.

Low sound level. (<85 dB)

Low vibration. (Average <2.5 m/s)

Safety Tools Allmet - Since 1998

We are experts in training, usage and maintenance of our cold solutions. We can document years worth of good feedback from customers worldwide.